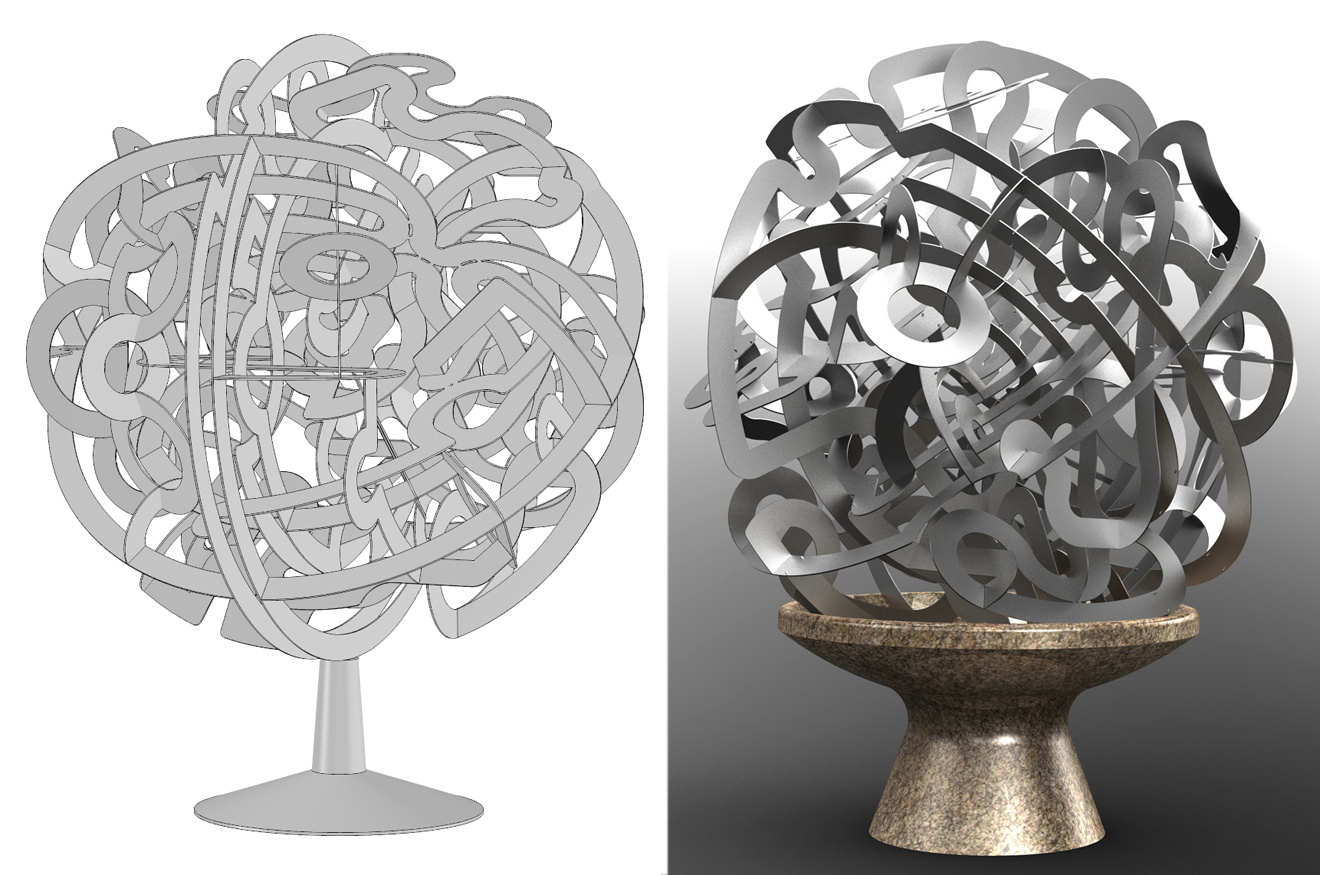

Percorso di Vita

2012 304 Stainless steel, cement coated fiberglass base

81 × 48 × 48 ″

This piece was created as a response to The Spirit of The Man, an outdoor exhibition at Paradise Ridge Winery. Curated by Debra Lehane on behalf of the Voigt Family Sculpture Foundation, the exhibit opened in the Spring of 2012, and was to run for one year. However, due to popular demand, it was extended to two.

As part of the exhibit, I wrote an artist’s statement:

The life of an artist is molded and influenced by both internal and external forces. At times, seminal moments appear, opening doors to different ways of thinking and working. My sculptures have up until now been for indoor venues, being made of wood, plastics, and metals combined to make kinetic interactive labyrinths. In direct response to Al Voigt's predilection towards metal as well as outdoor sculpture, I worked to create a piece that not only fits his passion, but to also reflect his life in a way that is universal, and true to my visual parlance.

Percorso di Vita, or path of life, is a special three-dimensional labyrinth meant to depict the complexity, interconnectedness, and never-ending cycle of life. There is no beginning or end, only a continuum, which eventually loops upon itself only to begin the journey again. Although one can discern individual parts assembled into the whole, no part stands alone, or is complete without its related elements. This one single path, at many times intersected and redirected, reveals a life well-lived, where choices were made and paths defined, yet held to a sphere of influence, individuality, and wholeness.

One can interact with the work by running a finger along the path, or by visually following its route. If followed back to the initial starting point, all surfaces within the piece will have been traversed. It is in this process that one truly begins to grasp its interconnected nature. It is very difficult to take in its entirety, as with the entirety of Al Voigt’s life, other than to become fully engaged.

A special thanks to The Voigt Family Sculpture Foundation for including me in this exhibit, and to James Yonts who assisted me in building this piece.

Designing the piece

An overriding desire in designing Percorso di Vita was to create an outdoor piece in a scale capable of competing with and complementing its surroundings. Stainless steel was an attractive medium because of its durability and light, neutral tone. I entertained other materials such as copper, bronze, UV stabilized plastics, aluminum (anodized and natural), Cor-ten (weathering steel), and galvanized steel. Because stainless does not readily oxidize, I felt that it would be most appropriate for this piece. Its finish would remain unchanged for the longest period of time, and for this exhibit I wanted the work to maintain its appearance from opening day to closing, and far beyond.

Several factors determined its scale, but the main ones were material availability, structural stability and portability. I decided that a 48-inch diameter was appropriate. For one thing, it would fit in the back of my pickup truck. Also, readily available sheet goods come in 48 x 96, 48 x 120 and 60 x 120. I wanted as many individual parts as possible to span the full width of the work for structural integrity.

Since Percorso di Vita is a static piece, it needed no gimbal. However, since it is based upon a sphere, it did require a base to accommodate the form. Originally I intended on making a post and plate. This idea had flaws. It could not form enough of a support structure to withstand lateral forces on the superstructure. Further, it defined the piece as having a top and bottom, since it was affixed to the pathway. Instead, I came up with a vessel design that cradled the superstructure, giving the labyrinth a feeling of being placed into the base rather than being mounted on it. I wanted a dynamic feeling, as though a giant gently set it down for a moment.

I intended on making the vessel from concrete, which required either direct forming, or casting into a mold. At this point, the due date was rapidly closing in, so I decided to have a custom fabricator make the base instead of me... until I received his bid. James suggested looking at fountains and statuary for pre-made giant bowls. I found many online, but none available locally. On a tour of nearly every statuary supplier in the county, I stumbled upon a fountain that expressed my desires perfectly. Absolute Statuary and Fountains, inc. had a piece made from cement over fiberglass. It was heavy and expensive, but still much less than the price of a custom made piece. I could have built my own for substantially less, but there simply was no time available. Before purchasing, I took accurate measurements, went home, and within an hour drew it in CAD and made a rendering to ensure its appropriateness. The supplier was willing to stain the piece to a weathered brown to clean it up and match my rendering.

Making Percorso di Vita required the use of a process new to me: waterjet, which is capable of cutting complex and fine details in a wide variety materials, including metals, glass, stone, and more. Waterjet employs the use of abrasives injected into a high pressure stream of water controlled by a computer. The process is akin to that of my CNC router, but instead of a cutter head there is the jet. Unlike my CNC router, waterjet cannot remove large swaths of material, make dado cuts, or cut topographical forms. It can only make through-cuts. The water itself is very powerful, and capable of severe damage, but can only cut softer materials. The addition of garnet or other fine abrasives increases the cutting power by magnitudes. Abrasive is added just prior to reaching the sapphire nozzle. I did not (and do not) have my own waterjet machine, and needed to find a service in the area. I located a company in American Canyon called Triton Waterjet and Design, Inc, who could complete my request in a timely manner.

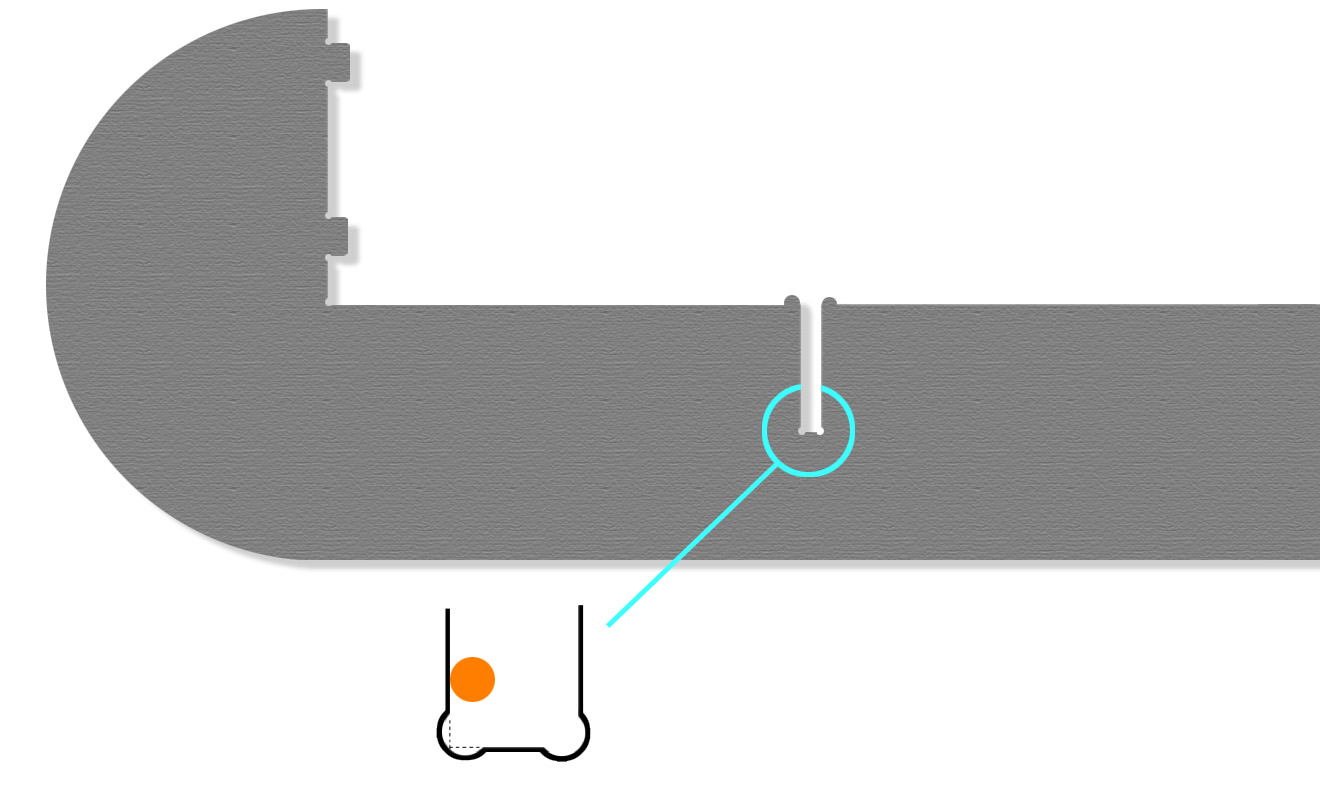

As is typical of my Superplexus work, it took many hundreds of hours to design. I had to take into account the new cutting process, creating blips at every inside corner. A blip in this context is a small amount of material removed from the inner corner of a cut to accommodate the diameter of the cutter, ensuring that another part can fit tightly against that corner. My aesthetic for this piece was to have very clean lines and the thinness of the material unaffected by weld points. I had to work out a joinery method that was clean, and required nothing more than cold connections, cut out at the same time as the parts themselves. Where parts crossed through one-another, I designed slots with extended tabs that could be interlocked and hammered over to pinch them together. Where one part teed into another, I created double through-cut mortise and tenon joints. The protruding tenons were punched-over, forming a locking connection.

Unfortunately, I designed the piece as though it was to be cut from ⅛″ material, but in reality, 12 GA stainless steel is 0.1406 inches thick, so after working out the design, I had to redo all parts thicknesses and connection points.

Making the piece

Upon 3D-design completion in SpaceClaim, I laid the 50 pieces onto one plane, exported this as a 2D DXF file, opened that in VCarvePro, arranged the parts onto sheet sizes appropriate for the material and cut stream diameter, and sent clean vector files to Triton. They created cut paths from my layouts and jetted the pieces. Although they did a wonderful job cutting, they heavily scratched many of the pieces by dragging them across the waterjet table. 304 (or 18-8) Stainless steel is an expensive material that is used for food-grade equipment, which I desired since my work is meant to be touched. Careful handling of costly materials meant for aesthetic purposes is of obvious importance.

These scratches needed to be removed in a way that maintained the smooth appearance of the sheet, so grinding was out. I considered sand blasting but did not have large enough equipment to make the consistent finish I desired. Instead, I chose to sand the surface. Taking the scratches out took James and I several days of wet sanding with power equipment and by hand. Since the sanding altered the original mill grade finish, all 50 pieces required similar sanding to equalize their finish. This turned out to be a blessing, as I discovered that sanding very carefully along the curves by hand gave the exact finish I desired; a movement of light along the lines mimicking the flow of a river. The pieces became alive. Waterjet cutting leaves a sharp, slightly beveled edge. This had very little line of light, the property of reflection that highlights an edge. For safety and a stronger line of light, all 953′ of exposed edging needed filing and sanding.

Assembling was a delicate process because the surfaces already had their fine undulating lines, and the metal parts were heavy and fairly flexible. Fitting was almost entirely a two-person job. Setting the tabs and through-mortises was noisy, requiring earphones for protection. It must have been a constant irritation to the neighbors. I made a gross error in assembly order, and one piece became impossible to fit without cutting one of its pathways in half. I should have fit that piece at a much earlier stage, but it was too late. Stainless steel can be silver-soldered, which does not melt or distort the sheet. In order to make as thin a cut as possible, I used a jeweler’s saw. This was insane, and took about an hour to cut 2 inches. The joint was placed at a diagonal to a tee-mortise to minimize its appearance and increase its strength. Presently, I have no idea where that repair is in the piece.

Upon final assembly and touch-up, the piece was placed on its base. It was rotated and positioned to create diagonals and sight lines, ready for delivery to Paradise Ridge.

The base and labyrinth had to be transported independently since it was far too heavy and awkward to carry whole. At the site, we ran coated stranded wires around major labyrinth parts, pulled the wires through the center of the base (which already had a hole through its center from its days as a fountain, which also became a convenient rain drain) and anchored them to metal stakes in the ground surrounding the piece. They all but became invisible, and provided security from wind and wild art enthusiasts.